YUNNAN Economical CNC Lathe CY-K510n

Characteristic

●The specially designed Independent Spindle structure ensures the maximum heat dissipation and brings down the heat distortion.

●Unique design brings high precision, high rigidity and low noise performance in turning.

●Automatic 3-step gear box with inverter is standard spindle drive, while servo motor drive as optional.

●The optional Teach-In function of CY-K series makes the quick and simple setup, programming and easy to operate.

●Electronic handwheels with Teach-In function is optional.

|

Item |

Unit |

CY-K510n |

||

|

Swing over bed |

mm |

Φ510 |

||

|

Max.working diameter

|

Disc |

mm |

Φ500 |

|

|

Shaft |

mm |

Φ270 |

||

|

Max. turning length |

550 |

mm |

- |

|

|

750 |

670 |

|||

|

1000 |

920 |

|||

|

Swing over cross slide |

mm |

290 |

||

|

Width of Z axis |

mm |

390 |

||

|

Width of X axis |

mm |

210 |

||

|

Spindle nose |

A2-8 |

|||

|

Taper hole of spindle |

Φ90,1:20 |

|||

|

Spindle bore |

mm |

Φ82 |

||

|

Maximum diameter of the bar getting through (for hollow chuck) |

mm |

Φ80 Manual chuck |

||

|

Spindle speed |

r/min |

35-160,140-620,580-2500 |

||

|

Maximum torque of spindle |

Nm |

780 |

||

|

Spindle steps |

Automatic 3-step grear box with inverter |

|||

|

Main motor |

30 minute rating |

kW |

- |

|

|

Continuous rating |

kW |

7.5 |

||

|

Rapid feed speed X axis |

m/min |

4 |

||

|

Rapid feed speed Z axis |

m/min |

8 |

||

|

Max. travel X axis |

mm |

250 |

||

|

Max.travel Z axis |

mm |

730/980/1480/1980 |

||

|

Tailstock quill diameter |

mm |

Φ75 |

||

|

Tailstock quill Max. travel |

mm |

150 |

||

|

Tailstock quill taper |

Morse |

MT5 |

||

|

Dimension of Tool |

Excircle tool |

mm |

25x25 |

|

|

Diameter of boring tool rod |

mm |

Φ25 |

||

|

Center height |

The distance of center height to bed |

mm |

250 |

|

|

The distance of center height to the ground |

mm |

1149 |

||

|

Overall dimensions (LxWxH) |

550 |

mm |

- |

|

|

750 |

2850×1700×1700 |

|||

|

1000 |

3100×1700×1700 |

|||

|

1500 |

3600×1700×1700 |

|||

|

2000 |

4100×1700×1700 |

|||

|

Package dimensions |

550 |

mm |

- |

|

|

750 |

3050×2000×2200 |

|||

|

1000 |

3300×2000×2200 |

|||

|

1500 |

4000×2000×2200 |

|||

|

2000 |

4500×2000×2200 |

|||

|

Gress/Net weight |

550 |

kg |

- |

|

|

750 |

2800/2400 |

|||

|

1000 |

2900/2500 |

|||

|

1500 |

3250/2750 |

|||

|

2000 |

4100/3500 |

|||

Configuration

|

Item |

Modle |

Producer |

Option |

|

Controller system |

GSK980TDc |

● |

|

|

FANUC 0i-TF(5) |

★ |

||

|

SIEMENS 828D |

★ |

||

|

Main motor |

Y132M-4-B3 |

7.5KW regular motor + Automatic gear box with inverter |

● |

|

Spindle bearing |

NN3022K/W33(110×170×45) |

Domestic Precision Bearing |

● |

|

NN3024K/W33 (120×180×46) |

|||

|

7024ACP4/DB(120×180×56) |

|||

|

X-axis screw |

Φ25×5×488-P4 |

Domestic Precision Screw |

● |

|

Z-axis screw |

Φ40×10×1343-P4 |

750 Domestic Precision Screw |

● |

|

Φ40×10×1593-P4 |

1000 Domestic Precision Screw |

● |

|

|

Φ40×10×2093-P4 |

1500 Domestic Precision Screw |

● |

|

|

Φ40×10×2593-P4 |

2000 Domestic Precision Screw |

● |

|

|

X-axis screw bearing |

7602020TN/DBA(20×47×14) |

Domestic Precision Screw Bearing |

● |

|

Z-axis screw bearing |

6305/P5 |

Domestic Precision Screw Bearing |

● |

|

51207/P4 |

● |

||

|

6207/P5 |

● |

||

|

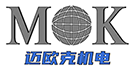

Tailstock |

Manual tailstock |

Self-made |

● |

|

Manual tailstock bearing bearing |

51204 ( 20×40×14) |

Domestic Precision Bearing |

● |

|

607(7×19×6) |

|||

|

Cooling pump |

AYB-25TH |

● |

|

|

Spindle belt |

9J(4)1660 |

Domestic well-known brand |

●

|

|

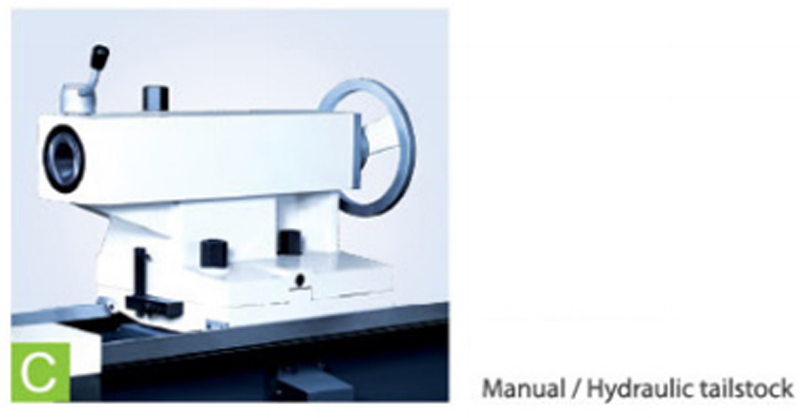

Turret |

HAK21192 |

Changzhou Vertical 4-postition electronic turret (Outer-Cooling) |

● |

Stander configuration● Optional configuration★