China Cnc Gun Drilling Machine – XINYUE Spline Rolling Machine CZ-24NCS 36NCS 48NCS – Maiouke

China Cnc Gun Drilling Machine – XINYUE Spline Rolling Machine CZ-24NCS 36NCS 48NCS – Maiouke Detail:

Specification

|

Technical Parameter |

Unit |

CZ-24NCS |

CZ-36NCS |

CZ-48NCS |

|

Loaded Tool Length |

Inch |

24 |

36 |

48 |

|

Max. Module |

m |

1.25 |

1.75 |

2.00 |

|

Max. Teeth Diameter |

mm |

40 |

50 |

60 |

|

Workpiece Length |

mm |

800 |

800 |

800 |

|

Cylindricity |

mm |

0.015 |

0.015 |

0.02 |

|

Roughness |

μm |

0.4-1.6 |

0.4-1.6 |

0.4-1.6 |

|

Max. Roll Forming Length |

mm |

100 |

120 |

150 |

|

Roll Forming Capacity Factor |

mm |

50 |

70 |

100 |

Characteristic

1. Cumulative adjustment of circumferential distance

This innovation makes it easy to compensate for deviations in tool symmetry, completely solving problems that must be handled by tedious mechanical or shim adjustments. Better cumulative accuracy of circumferential pitch can be achieved.

2. Optimized synchronization of the main slide

The control system adopts nano-level calculation to make synchronization performance better than gear synchronization or gearbox synchronization.

3. Multi-stage CNC roll forming

Full CNC machine can complete multi-stage roll forming with different parameters on the same workpiece, which is called the king of roll forming.

4. CNC Motor Drive With Low Energy Consumption

Compared with hydraulic drive, CNC-drive saves 70% energy, which meets the needs of the times. So it is low consumption high efficient equipment in the true sense.

5. High Performance With Less Procedures

Multi-stage processing technology reduces labor intensity, making it possible for a person to operate multiple devices; and it also reduces product flow, uses less procedures and reduces product clashes.

6. Horizontal Pre-Pull Structure

The optimized internal stiffener arrangement and six-sided frame, and domestic patented combination sliding stud connection greatly enhance the overall rigidity, stability, reliability, security, which guarantees a longer service life of the machine.

7. User-Friendly Operation Interface

The system can display fault information, processing count, timing, storage program, detection of the total length of the workpiece, anti- faulty or empty clamping, self-learning and so on.

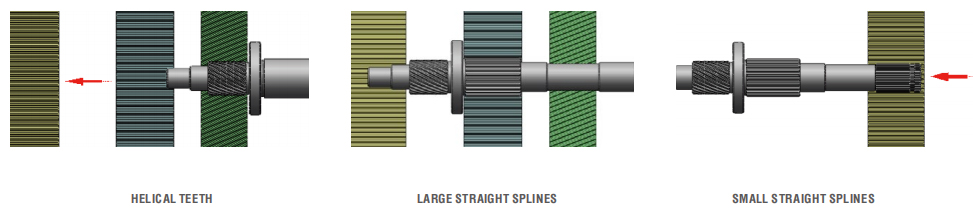

Parts Machined By Roll Forming Machine

Suitable for straight teeth and helical gear teeth on various shaft parts such as gearbox gear shaft, cage constant velocity universal joint, spline shaft, motor shaft, textile roller, spring torsion bar, steering gear, crankshaft, etc.

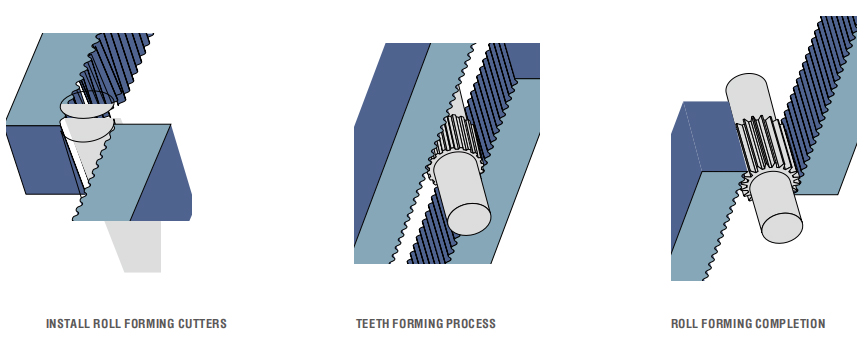

Roll forming machine roll forming process

Multi-stage roll forming process

Processing principles

The principles of cold-roll forming are that the roll forming cutter dies installed on the sliding table operate in opposite linear motion. The workpiece splines are formed by the increasing teeth amount of the roll forming cutters, and the final shaping precision and stability of the splines are obtained by the rigid distance between the two roll forming cutters. The opposite linear movements of the roll forming cutters are driven by hydraulic machine and the high synchronization of the two roll forming cutters is guaranteed by the racks and pinions. The synchronization of two roll forming cutters is guaranteed by the ball screws on the CNC machine. (Its synchronization accuracy is higher)

Product detail pictures:

Related Product Guide:

abide by the contract", conforms towards the market requirement, joins during the market competition by its good quality likewise as provides additional comprehensive and great services for customers to let them turn out to be big winner. The pursue of your enterprise, is the clients' fulfillment for China Cnc Gun Drilling Machine – XINYUE Spline Rolling Machine CZ-24NCS 36NCS 48NCS – Maiouke , The product will supply to all over the world, such as: Niger, Mongolia, Pakistan, Many years of work experience, we have now realized the importance of providing good quality products and solutions and the best before-sales and after-sales services. Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. faster delivery time and the product you want is our Criterion .

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!