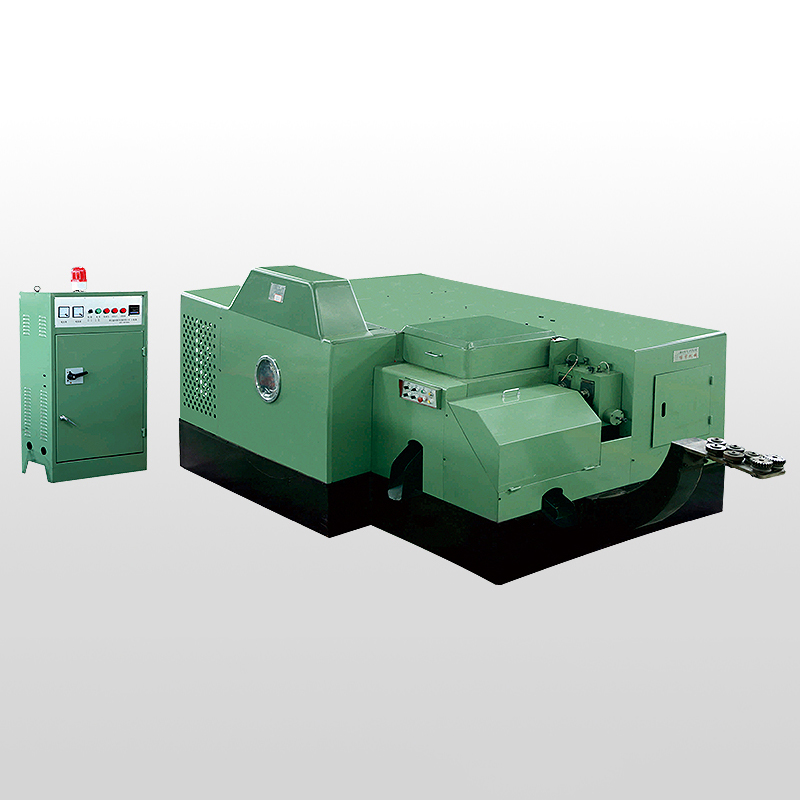

China Double-Sided Lathe Manufacturers – YUNNAN Economical CNC Lathe CY-K510n – Maiouke

China Double-Sided Lathe Manufacturers – YUNNAN Economical CNC Lathe CY-K510n – Maiouke Detail:

Characteristic

●The specially designed Independent Spindle structure ensures the maximum heat dissipation and brings down the heat distortion.

●Unique design brings high precision, high rigidity and low noise performance in turning.

●Automatic 3-step gear box with inverter is standard spindle drive, while servo motor drive as optional.

●The optional Teach-In function of CY-K series makes the quick and simple setup, programming and easy to operate.

●Electronic handwheels with Teach-In function is optional.

|

Item |

Unit |

CY-K510n |

||

|

Swing over bed |

mm |

Φ510 |

||

|

Max.working diameter

|

Disc |

mm |

Φ500 |

|

|

Shaft |

mm |

Φ270 |

||

|

Max. turning length |

550 |

mm |

- |

|

|

750 |

670 |

|||

|

1000 |

920 |

|||

|

Swing over cross slide |

mm |

290 |

||

|

Width of Z axis |

mm |

390 |

||

|

Width of X axis |

mm |

210 |

||

|

Spindle nose |

A2-8 |

|||

|

Taper hole of spindle |

Φ90,1:20 |

|||

|

Spindle bore |

mm |

Φ82 |

||

|

Maximum diameter of the bar getting through (for hollow chuck) |

mm |

Φ80 Manual chuck |

||

|

Spindle speed |

r/min |

35-160,140-620,580-2500 |

||

|

Maximum torque of spindle |

Nm |

780 |

||

|

Spindle steps |

Automatic 3-step grear box with inverter |

|||

|

Main motor |

30 minute rating |

kW |

- |

|

|

Continuous rating |

kW |

7.5 |

||

|

Rapid feed speed X axis |

m/min |

4 |

||

|

Rapid feed speed Z axis |

m/min |

8 |

||

|

Max. travel X axis |

mm |

250 |

||

|

Max.travel Z axis |

mm |

730/980/1480/1980 |

||

|

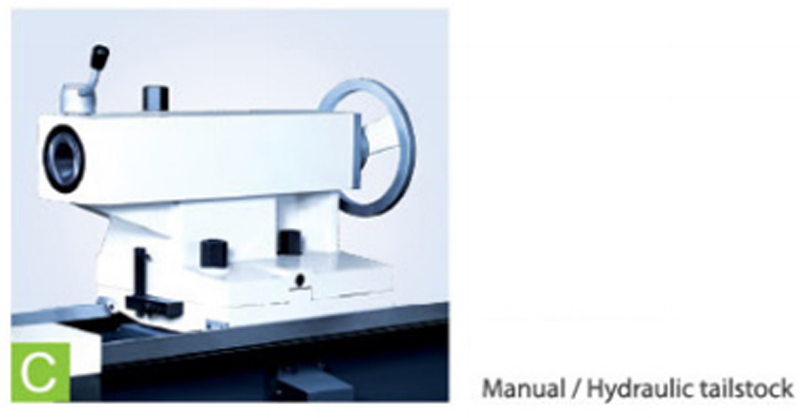

Tailstock quill diameter |

mm |

Φ75 |

||

|

Tailstock quill Max. travel |

mm |

150 |

||

|

Tailstock quill taper |

Morse |

MT5 |

||

|

Dimension of Tool |

Excircle tool |

mm |

25×25 |

|

|

Diameter of boring tool rod |

mm |

Φ25 |

||

|

Center height |

The distance of center height to bed |

mm |

250 |

|

|

The distance of center height to the ground |

mm |

1149 |

||

|

Overall dimensions (LxWxH) |

550 |

mm |

- |

|

|

750 |

2850×1700×1700 |

|||

|

1000 |

3100×1700×1700 |

|||

|

1500 |

3600×1700×1700 |

|||

|

2000 |

4100×1700×1700 |

|||

|

Package dimensions |

550 |

mm |

- |

|

|

750 |

3050×2000×2200 |

|||

|

1000 |

3300×2000×2200 |

|||

|

1500 |

4000×2000×2200 |

|||

|

2000 |

4500×2000×2200 |

|||

|

Gress/Net weight |

550 |

kg |

- |

|

|

750 |

2800/2400 |

|||

|

1000 |

2900/2500 |

|||

|

1500 |

3250/2750 |

|||

|

2000 |

4100/3500 |

|||

Configuration

|

Item |

Modle |

Producer |

Option |

|

Controller system |

GSK980TDc |

● |

|

|

FANUC 0i-TF(5) |

★ |

||

|

SIEMENS 828D |

★ |

||

|

Main motor |

Y132M-4-B3 |

7.5KW regular motor + Automatic gear box with inverter |

● |

|

Spindle bearing |

NN3022K/W33(110×170×45) |

Domestic Precision Bearing |

● |

|

NN3024K/W33 (120×180×46) |

|||

|

7024ACP4/DB(120×180×56) |

|||

|

X-axis screw |

Φ25×5×488-P4 |

Domestic Precision Screw |

● |

|

Z-axis screw |

Φ40×10×1343-P4 |

750 Domestic Precision Screw |

● |

|

Φ40×10×1593-P4 |

1000 Domestic Precision Screw |

● |

|

|

Φ40×10×2093-P4 |

1500 Domestic Precision Screw |

● |

|

|

Φ40×10×2593-P4 |

2000 Domestic Precision Screw |

● |

|

|

X-axis screw bearing |

7602020TN/DBA(20×47×14) |

Domestic Precision Screw Bearing |

● |

|

Z-axis screw bearing |

6305/P5 |

Domestic Precision Screw Bearing |

● |

|

51207/P4 |

● |

||

|

6207/P5 |

● |

||

|

Tailstock |

Manual tailstock |

Self-made |

● |

|

Manual tailstock bearing bearing |

51204 ( 20×40×14) |

Domestic Precision Bearing |

● |

|

607(7×19×6) |

|||

|

Cooling pump |

AYB-25TH |

● |

|

|

Spindle belt |

9J(4)1660 |

Domestic well-known brand |

●

|

|

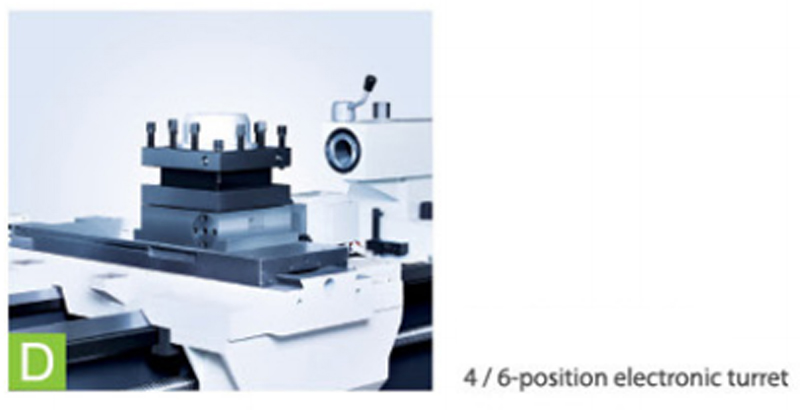

Turret |

HAK21192 |

Changzhou Vertical 4-postition electronic turret (Outer-Cooling) |

● |

Stander configuration● Optional configuration★

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for China Double-Sided Lathe Manufacturers – YUNNAN Economical CNC Lathe CY-K510n – Maiouke , The product will supply to all over the world, such as: Costa Rica, Oman, Cape Town, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.