China Pipe Threading Lathe Q1319 Manufacturers – YUNNAN Gap Bed Manual Lathe CY6250B CY6266B CY6276L – Maiouke

China Pipe Threading Lathe Q1319 Manufacturers – YUNNAN Gap Bed Manual Lathe CY6250B CY6266B CY6276L – Maiouke Detail:

Characteristic

The headstock gear-box, apron and bed-ways are made of high quality casting iron, and are all casting with the resin sand foundry technology and aging process. The bed ways are induction-hardened, with hardness around HRC 52.

The spindle supported by 3-pointed high-precision bearings and all gears in headstock are precisely grinded, the spindle turns smoothly at high speed. High rigidity spindle system, with absolute temperature rising no higher than 35*C .

Rapid feed system to improve efficiency. Wide range of feed and pitch are available without changing gears, distance between centers 1000 – 5000mm, this lathe covers wide range of working pieces.

When rapid feeding is on, the tool slide longitudinal travel hand-wheel will be automatically disfunctioned.

Reliable safety devices such as footbrake and emergency power-off switch are assembled. Adjustable overload protection device is also installed in the feed system.

The tool post adopts the structure of ratchet pawl, and can be relocked by turning the lever for just half a lap.

Tailstock are equipped with double-locked mechanism, smooth and effortless movement is ensured by the elastic scroll devices underneath.

|

item |

unit |

CY6250 |

CY6266 |

CY6276L |

|||||

|

A |

B |

L |

B |

L |

|||||

|

swing over bed |

mm |

500 |

660 |

760 |

|||||

|

swing over cross slide |

mm |

300 |

430 |

530 |

|||||

|

Dis. between centers |

mm |

1000/1500/2000/3000mm |

|||||||

|

spindle nose |

C6 |

D8 |

|||||||

|

Stander 3-jaw chuck |

K11250C/C6 |

K11250C/D8 |

K11325C/D8 |

K11325C/D8 |

K11325C/D8 |

||||

|

Spindle diameter |

mm |

52 |

82 |

105 |

82 |

105 |

105 |

||

|

spindle speed |

rpm |

9-1600 24steps |

9-1600 (24step) |

6-1120 (24steps) |

9-1600 (24steps) |

6-1120 (24steps) |

6-1120 (24steps) |

||

|

Spindle max output torque(30mins) |

N.M |

1400 |

2000 |

2000 |

|||||

|

range of longitudinal feed |

mm/rev |

0-028- 6.43 |

0-028- 6.43 |

0.063- 6.43 |

0-028- 6.43 |

0.063- 6.43 |

0.063- 6.43 |

||

|

range of cross feed |

mm/rev |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

0.012- 2.73 |

0.027- 2.73 |

0.027- 2.73 |

||

|

metric threads |

mm |

0.5-224 (48kinds) |

0.5-224 (48kinds) |

1-224 (46kinds) |

0.5-224 (48kinds) |

1-224 (46kinds) |

1-224 (46kinds) |

||

|

Inch system threads |

T.p.i | 72-1/8in(46kinds) | 72-1/8in(46kinds) | 28-1/8in(42kinds) | 72-1/8in(46kinds) | 28-1/8in(42kinds) | 28-1/8in(42kinds) | ||

|

module threads |

0.5-112(42kinds) |

||||||||

|

Dia.pitch threads |

Dp |

56-1/4(45kinds) |

|||||||

|

Main motor |

kw |

7.5 |

7.5 |

11 |

11 |

||||

|

cross slide travel |

mm |

340 |

370 |

||||||

|

Top silde travel |

mm |

145 |

200 |

||||||

|

longitudinal rapid traveling speed |

m/min |

4.5 |

4.5 |

||||||

|

transversal rapid traveling speed |

m/ min |

1.9 |

1.9 |

||||||

|

tailstock quill diameter |

mm |

75 |

75 |

||||||

|

Max travel of tailstock quill |

mm |

150 |

150 |

||||||

|

Taper of tailstock spindle |

M5 |

M5 |

|||||||

|

Cutter size |

mm |

25*25 |

25*25 |

||||||

|

Machine size |

mm |

2500/3000/3500/4500*1150*1300 |

2500/3000/3500/4500*1250*1400(76L:+100 on height) |

||||||

|

Net/gross weight |

kg |

2540/2100 2860/2400 3200/2800 4000/3800 |

2800/2200 3000/2500 3400/2900 4200/3400(76L:+100 on both) |

||||||

|

Wroking roundness |

0.01 |

||||||||

|

Working cylindricity |

0.04/300 |

||||||||

|

Working flatness |

0.025/Φ300 |

||||||||

|

Accuracy stander |

GB/T4020-1997 |

||||||||

Stander Configuration

1. 250mm 3-jaw chuck for 50B, 50L series;0325mm 3-jaw chuck for 66B, 66L, 76L series

2. Thread chasing dial

3. chip guard for L≤2m lathe,follow chip guard for L≤3m lathe

4. foot brake

5. oil gun

6. Live center 5#

7. center 5#

8. center sleeve

Optional Configuration

1. 630mm Face plate for 50 series

800mm Face plate for 66, 76 series

2. 400mm 4-jaw chuck

3. 20-140mm Small steady rest

4. 130-260mm Large steady rest

5. 2680mm Follow rest

6. 250mm Drive plate

7. 4-position stop for saddle

8. 4-position stop for cross slide

9. Micro stop for saddle

10. Quick change tool post

11. Damping washer

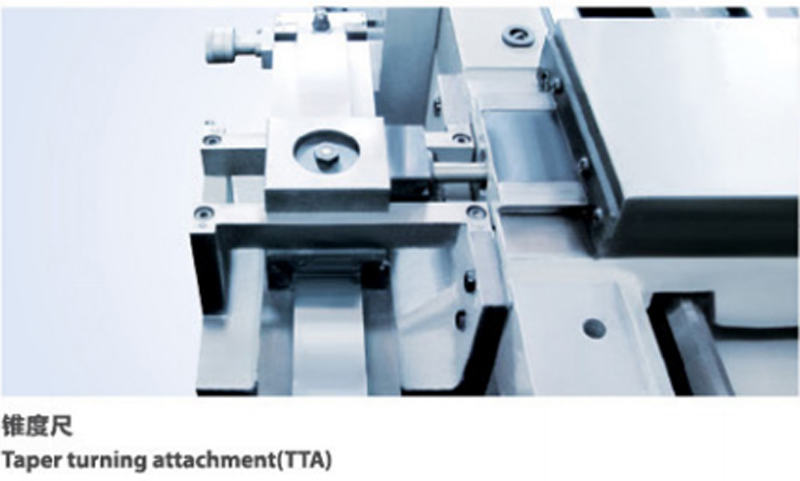

12. Taper turning attachment(TTA)

13. Halogen work lamp

14. Digital readout(DRO)

15. CE standard compliance

16. Chuck cover

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for China Pipe Threading Lathe Q1319 Manufacturers – YUNNAN Gap Bed Manual Lathe CY6250B CY6266B CY6276L – Maiouke , The product will supply to all over the world, such as: San Diego, Mombasa, Sweden, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.