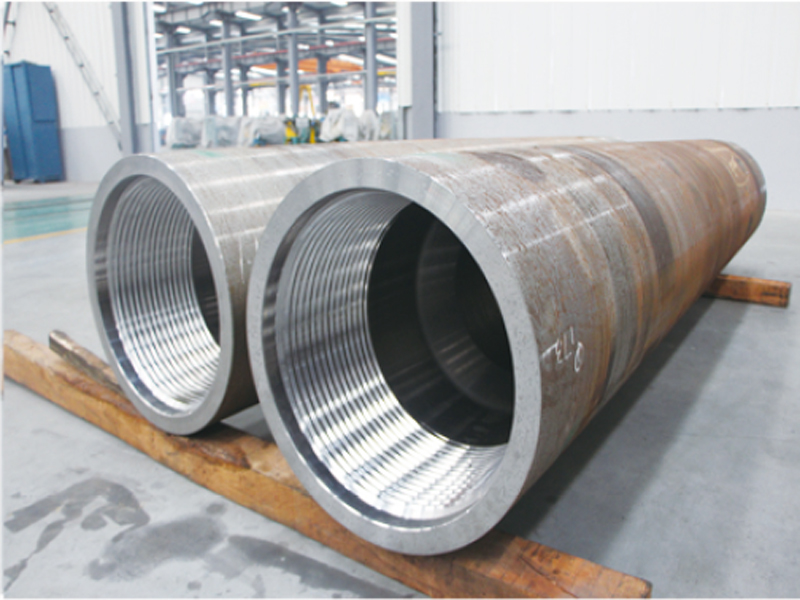

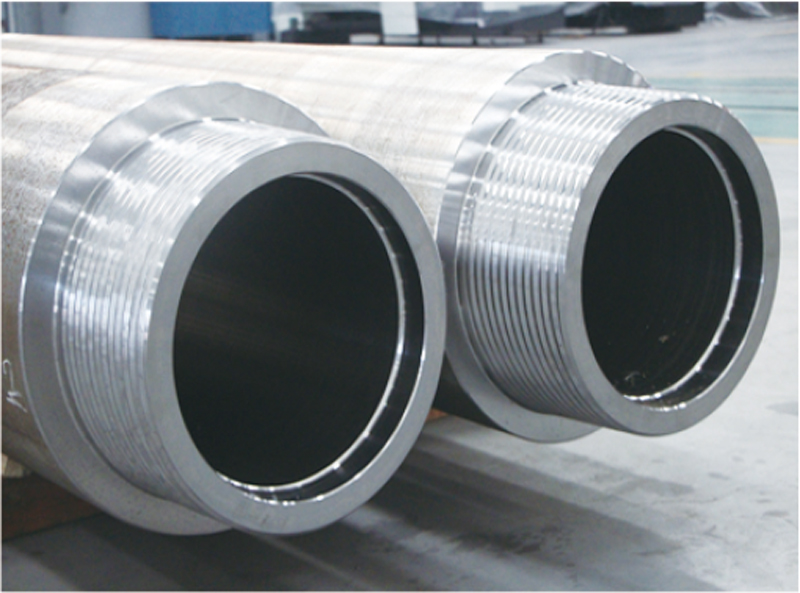

Europe style for CNC Cold Forming Steel Rebar Rib Peeling Rod Threading Machine

We stick to our company spirit of “Quality, Effectiveness, Innovation and Integrity”. We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for Europe style for CNC Cold Forming Steel Rebar Rib Peeling Rod Threading Machine, Our business maintains safe and sound business blended by truth and honesty to help keep long-term interactions with our buyers.

We stick to our company spirit of “Quality, Effectiveness, Innovation and Integrity”. We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for China Coupling Threading Machine and Electric Thread Rolling Machine, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

Specification

|

Item |

Unit |

QK1319 |

QK1322 |

QKD1335 |

QK1350 |

|||

|

Manual |

HYD |

Manual |

HYD |

|||||

|

Capacity |

Swing over bed |

mm |

630/800 |

630/800 |

900 |

1200 |

||

|

Swing over cross slide |

mm |

340/520 |

340/520 |

535 |

710 |

|||

|

Distance between centers |

mm |

1000-6000 |

1000-6000 |

1000-3000 |

1500/3000 |

|||

|

Guideway width |

mm |

50-193 |

50-220 |

110-340 |

330-510 |

|||

|

Max. load capacity |

mm |

550 |

550 |

755 |

765 |

|||

|

Spindle bore |

T |

3 |

3 |

5 |

6 |

|||

|

Spindle |

Spindle bore taper |

mm |

206 |

206 |

355 |

520 |

||

|

Spindle nose type |

- |

VF.4 steps |

HYD 4 steps |

VF.4 steps |

HYD 4 steps |

Stepless |

VF.3 steps |

|

|

Spindle speed range |

rpm |

20-600 |

20-600 |

90-450 |

8-190 |

|||

|

Chuck |

mm |

Φ500 3-jaw manual |

Φ500 3-jaw manual |

Φ780 4-jaw electric |

Φ1000 4-jaw electric |

|||

|

Turret |

Turret/tool post |

- |

NC turret 4 position |

NC turret 4 position |

NC turret 4 position |

NC turret 4 position |

||

|

Tool shank size |

mm |

32×32 |

32×32 |

40×40 |

50×50 |

|||

|

Feed |

X axis travel |

mm |

320/420 |

320/420 |

480 |

520 |

||

|

Z axis travel |

mm |

1000-6000 |

1000-6000 |

1000-3000 |

1250/2750 |

|||

|

X axis rapid traverse |

mm/min |

4000 |

4000 |

4000 |

4000 |

|||

|

Z axis rapid traverse |

mm/min |

6000 |

6000 |

6000 |

4000 |

|||

|

Tailstock |

Tailstock quill diameter |

mm |

Φ100 |

Φ100 |

- |

Φ160 |

||

|

Tailstock quill taper |

- |

MT5/MT6 |

MT5/MT6 |

- |

MT6 |

|||

|

Tailstock quill travel |

mm |

250 |

250 |

- |

300 |

|||

|

Motor |

Main spindle motor |

kW |

11 |

11 |

22 |

22 |

||

|

Coolant pump motor |

kW |

0.25 |

0.25 |

0.25 |

0.25 |

|||

|

Dimension |

Width×Height |

mm |

1880×1850 |

1880×1850 |

2050×2050 |

2300×2200 |

||

|

Length |

mm |

3300-8300 |

3300-8300 |

3952-5950 |

5000/6500 |

|||

|

Weight |

Net weight |

T |

4.6-8.6 |

4.7-8.7 |

10.9 |

15.0/16.0 |

||

|

Please note: machine bed length can customize according to real work demand, machine on this page can choose servo motor direct driving structure turning center with C axis.(QK1319 QK1322) machine bed length can customize according to real work demand, extra-long bed heavy duty lathe can customize simplified CNC pipe threading lathe without protective cover.(QK1350) |

||||||||

Characteristic

●Big spindle bore and double chuck to ensure process big diameter pipe.

●One-piece bed adopts high strength iron to ensure rigidity and precision.

●Ultrasonic frequency quenched guide-ways ensure good wear-resistance.

●Carriage and guide way contact surface use Turcite B to maintain accuracy.

Stander Configuration

1. Siemens controller

2. NC turret

3. Automatic Lubrication

4. Coolant Pump

5. Semi-shield

Optional Configuration

1. Fanuc or other brand CNC controller

2. Quick change tool post

3. Hydraulic turret or Power turret

4. Pneumatic chuck

5. Hydraulic tailstock

6. Pneumatic position limiter

7. Tool setting arm

8. Full-shieldWe stick to our company spirit of “Quality, Effectiveness, Innovation and Integrity”. We purpose to create far more value for our shoppers with our abundant resources, sophisticated machinery, experienced workers and exceptional expert services for Europe style for CNC Cold Forming Steel Rebar Rib Peeling Rod Threading Machine, Our business maintains safe and sound business blended by truth and honesty to help keep long-term interactions with our buyers.

Europe style for China Coupling Threading Machine and Electric Thread Rolling Machine, We have now a good reputation for stable quality goods, well received by customers at home and abroad. Our company would be guided by the idea of “Standing in Domestic Markets, Walking into International Markets”. We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!