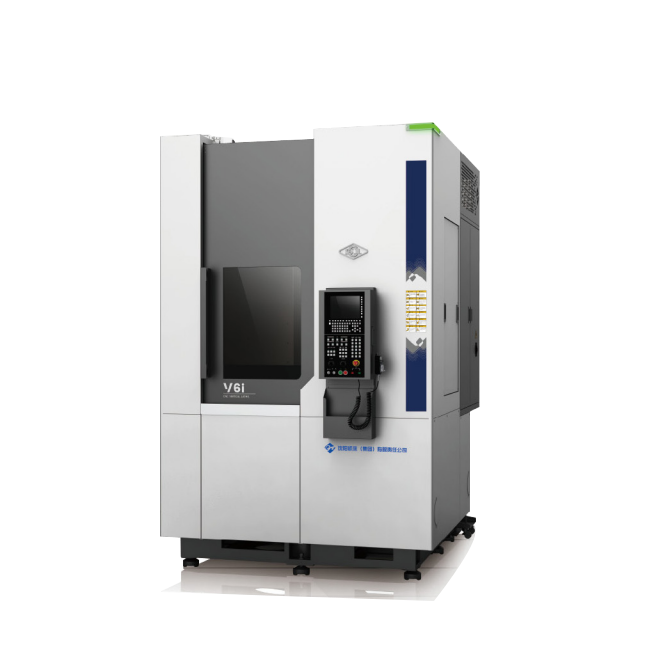

Factory supplied Vertical Machine Center CNC Lathe Vmc650 for Mechanical Processing and Mold Making

The client fulfillment is our primary concentrate on. We uphold a consistent level of professionalism, excellent, credibility and service for Factory supplied Vertical Machine Center CNC Lathe Vmc650 for Mechanical Processing and Mold Making, We attend seriously to produce and behave with integrity, and because of the favor of consumers in the home and abroad in the xxx industry.

The client fulfillment is our primary concentrate on. We uphold a consistent level of professionalism, excellent, credibility and service for China Lathe and Conventional Lathe, Our company regards “reasonable prices, high quality,efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

Specification

|

Item |

Unit |

V2S |

V4S |

V6C |

V6S |

| Processing capacity | |||||

|

Max Swing Diameter |

mm |

Φ500 |

Φ720 |

Φ860 |

Φ1000 |

|

Max Cutting Height |

mm |

350 |

650 |

700 |

800 |

|

Max Turning Diameter |

mm |

Φ330 |

Φ600 |

Φ800 |

Φ900 |

| Spindle | |||||

|

Spindle Nose |

- |

A2-8 |

A2-11 |

A2-11 |

A2-15 |

|

Speed |

r/min |

50-3000 |

50-2500 |

50-1500 |

50-800 |

|

Power |

kW |

15/18.5βMotor 11/15α Motor |

22/30 |

22/30 |

37/55 |

|

Max output torque |

Nm |

472βMotor 530α Motor |

1160 Domestic Motor 1159 α Motor |

1245 |

2000 |

|

Chuck Diameter |

inch |

10″ |

15″ |

21″ |

24″ |

| Feeding | |||||

|

X-axis Max Travel Speed |

m/min |

30 |

18 |

16 |

10 |

|

Z-axis Max Travel Speed |

m/min |

30 |

18 |

16 |

12 |

| Travel | |||||

|

X-axis Travel |

mm |

200 |

300 |

440 |

800 |

|

Z-axis Travel |

mm |

400 |

690 |

720 |

850 |

| Turret | |||||

|

Turret type |

- |

Horizontal 8-Station |

Horizontal 8-Station |

Horizontal 8-Station |

Vertical 6-Station |

|

Size of tool |

mm |

25×25/Φ40 |

25×25/Φ50 |

32×32/Φ50 |

32×32/Φ50 |

| Accuracy | |||||

|

Processing Accuracy |

- |

IT6 |

IT6-IT7 |

IT6-IT7 |

IT6-IT7 |

|

Surface Roughness of Finish Turning Outer Circle |

μm |

Ral. 25 |

Ral.6 |

Ral.6 |

Ral.6 |

| Positioning accuracy | |||||

|

X-axis |

- |

0.008 |

0.008 |

0.008 |

0.018 |

|

Z-axis |

mm |

0.008 |

0.008 |

0.010 |

0.020 |

| Repeat positioning accuracy | |||||

|

X-axis |

mm |

0.004 |

0.005 |

0.006 |

0.0075 |

|

Z-axis |

mm |

0.005 |

0.005 |

0.006 |

0.015 |

| Max. Loading | |||||

|

Disc |

kg |

300 |

400 |

600 |

800 |

| Machine Weight | |||||

|

Main machine |

kg |

4500 |

7300 |

10500 |

15000 |

| Machine size | |||||

|

L×W×H |

mm |

2000×1370×2275 |

2260×1780×3060 |

2700×2200×3300 |

3150×2650×3700 |

Characteristic

1.Integral external protection – Integral protection structure ensures waterproof performance

2.Lightweight inner sliding door – Lower working strength and better protection

3.Compact feed structure, using linear guide, fast moving speed, good machining accuracy, high reliability

4.Water tank make the overall layout more reasonable and occupy less space

5.Adopt servo main motor, which can provide better power performance

6.The bed has higher rigidity; the increased chip discharge angle is more conducive to chip discharge

The client fulfillment is our primary concentrate on. We uphold a consistent level of professionalism, excellent, credibility and service for Factory supplied Vertical Machine Center CNC Lathe Vmc650 for Mechanical Processing and Mold Making, We attend seriously to produce and behave with integrity, and because of the favor of consumers in the home and abroad in the xxx industry.

Factory supplied China Lathe and Conventional Lathe, Our company regards “reasonable prices, high quality,efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.