China Top Machinetools

News

-

Basic operation steps of Gap bed lathe

Gap bed lathe is a commonly used machine tool that works similarly to a common lathe but has higher machining accuracy and a wider application range. Gap bed lathe consists of a bed, spindle, feed mechanism, tool holder, and other parts. It is suitable for machining parts of various shapes. Gap b...Read more -

Several common Shenyang CNC vertical lathe repair and maintenance strategy

Shenyang CNC vertical lathes are widely used industrial equipment, and regular maintenance is essential to ensure their optimal performance. In this article, we will discuss several maintenance strategies for these CNC vertical lathes. 1. Cleaning Regular cleaning is key to maintaining CNC vertic...Read more -

CNC Turning Machine Repair

Daily use of CNC Turning Machine, often meet some fault problems. Having a basic understanding of the fault of CNC Turning Machine, simply distinguishing the cause of the fault and mastering simple repair methods can quickly restore the lathe to normal without causing serious loss to production. ...Read more -

CNC Flat Bed Lathe turning accuracy instability solution? Part-3

CNC Flat Bed Lathe turning accuracy instability solution? Part-3 7.CNC Flat Bed Lathe there is a change in the machining of one process of the workpiece, and the CNC Flat Bed Lathe dimensions of every other process are accurate. Cause of failure: Whether the program parameters of this program seg...Read more -

CNC Flat Bed Lathe turning accuracy instability solution? -Part 2

CNC Flat Bed Lathe turning accuracy instability solution? 4.processing arc effect is not ideal, small and medium-sized CNC Flat Bed Lathes are undersized. Failure causes: CNC Flat Bed Lathe resonance caused by overlapping vibration frequency; processing process; unreasonable parameter setting; to...Read more -

CNC Flat Bed Lathe turning accuracy instability solution?

CNC Flat Bed Lathe turning accuracy instability solution? What is the cause of unstable turning accuracy of CNC Flat Bed Lathe? CNC Flat Bed Lathe is mainly used for processing various precision parts, but sometimes there is unstable processing accuracy, what is the reason for this? According to ...Read more -

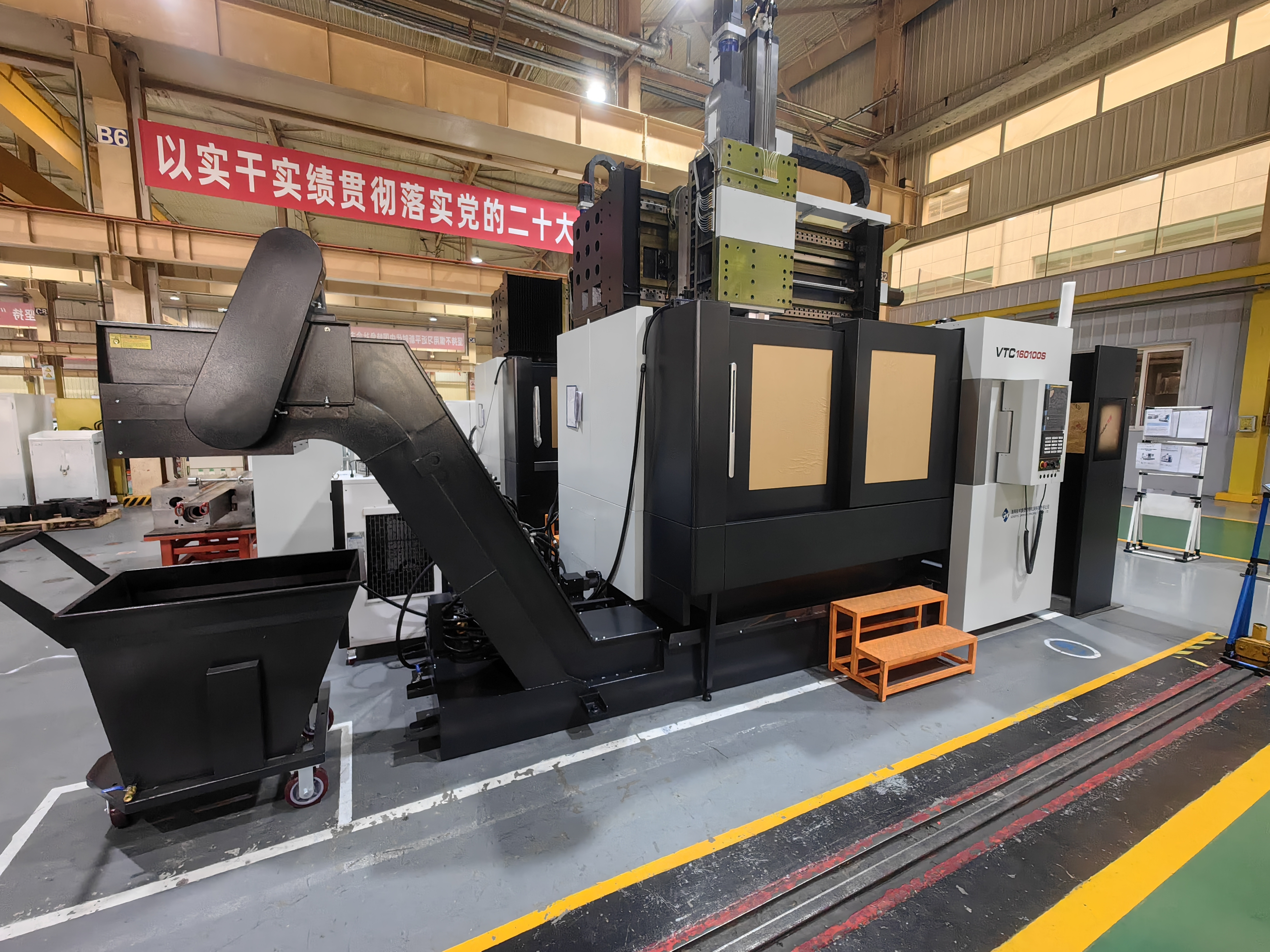

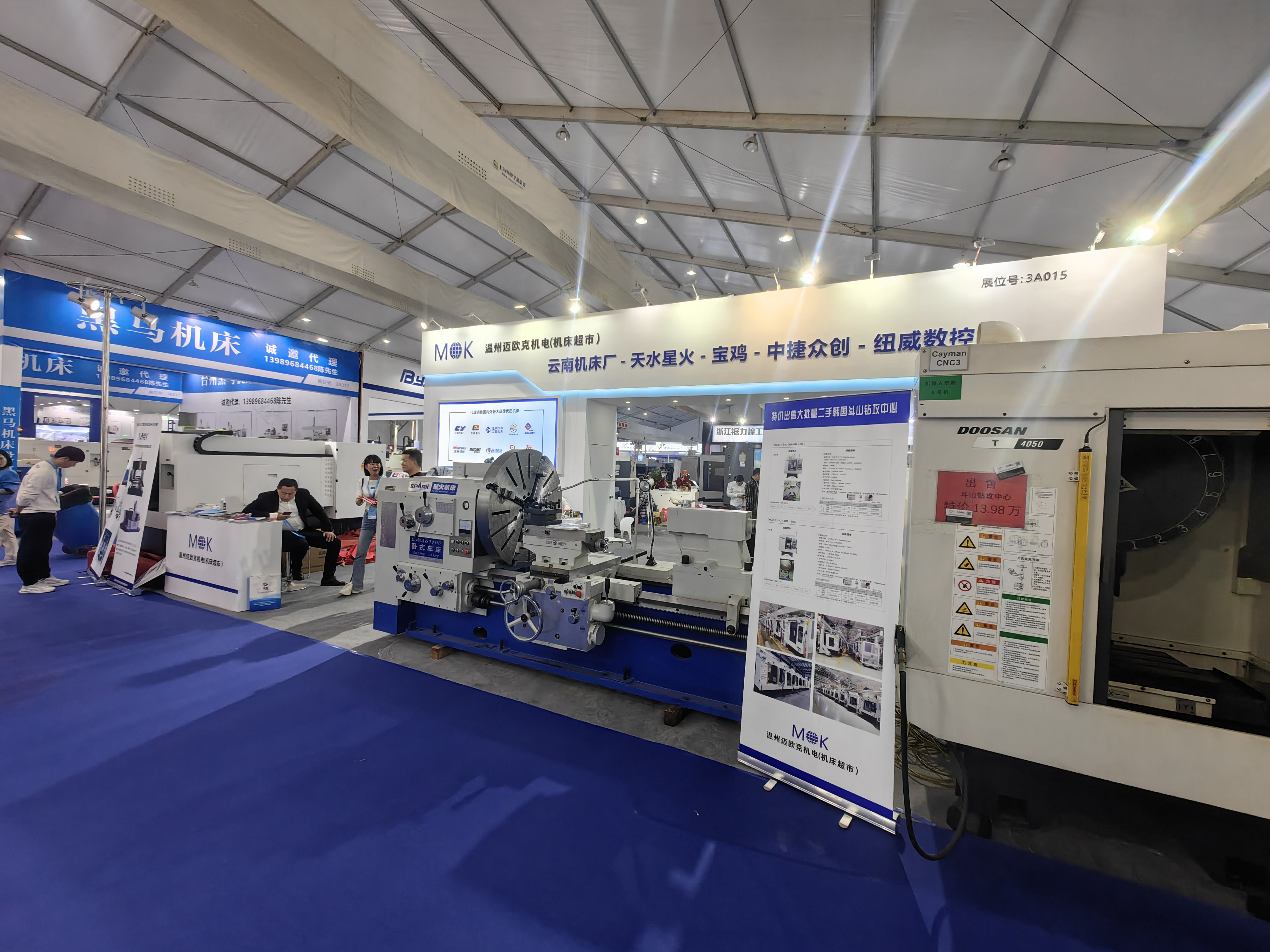

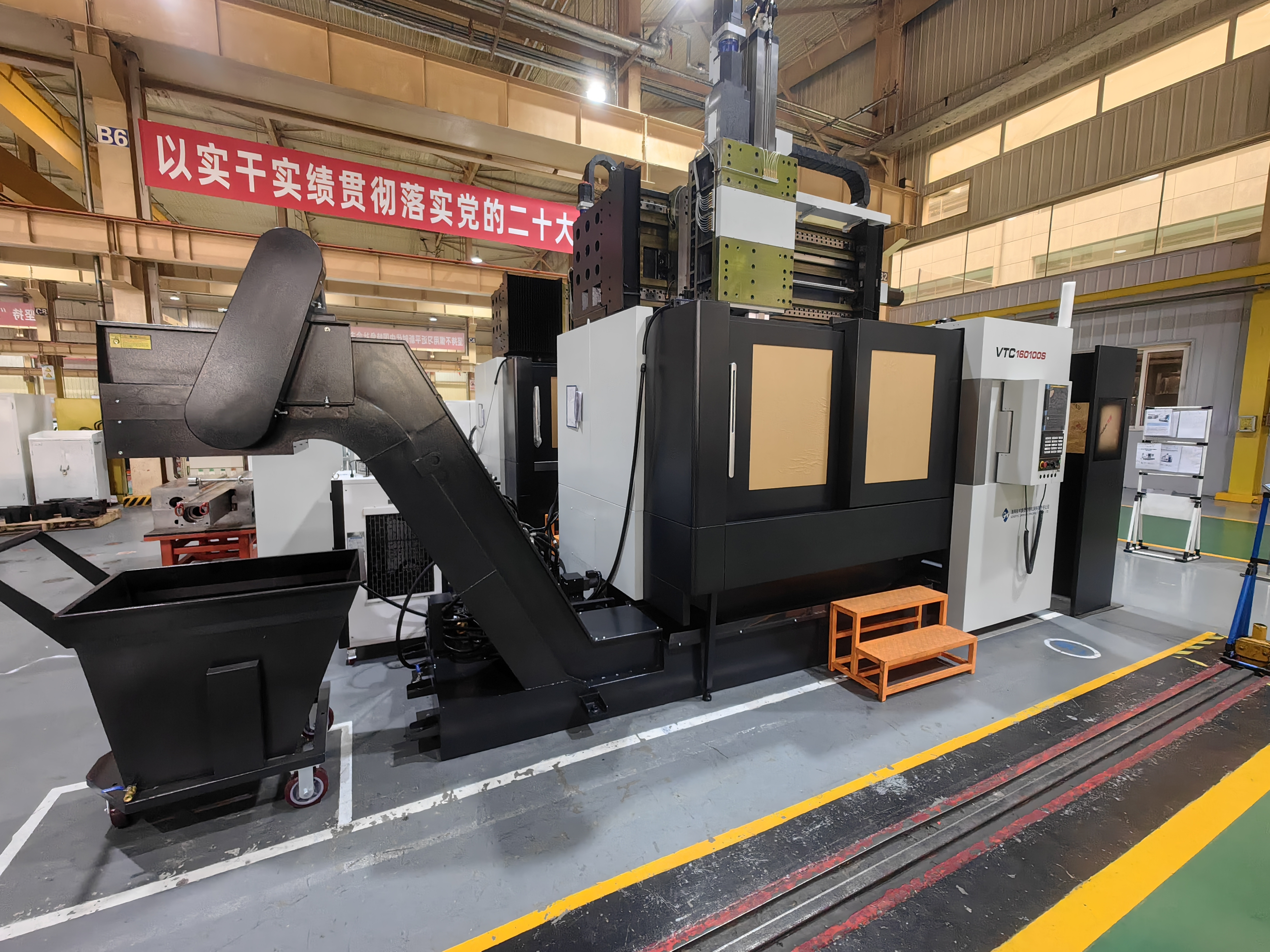

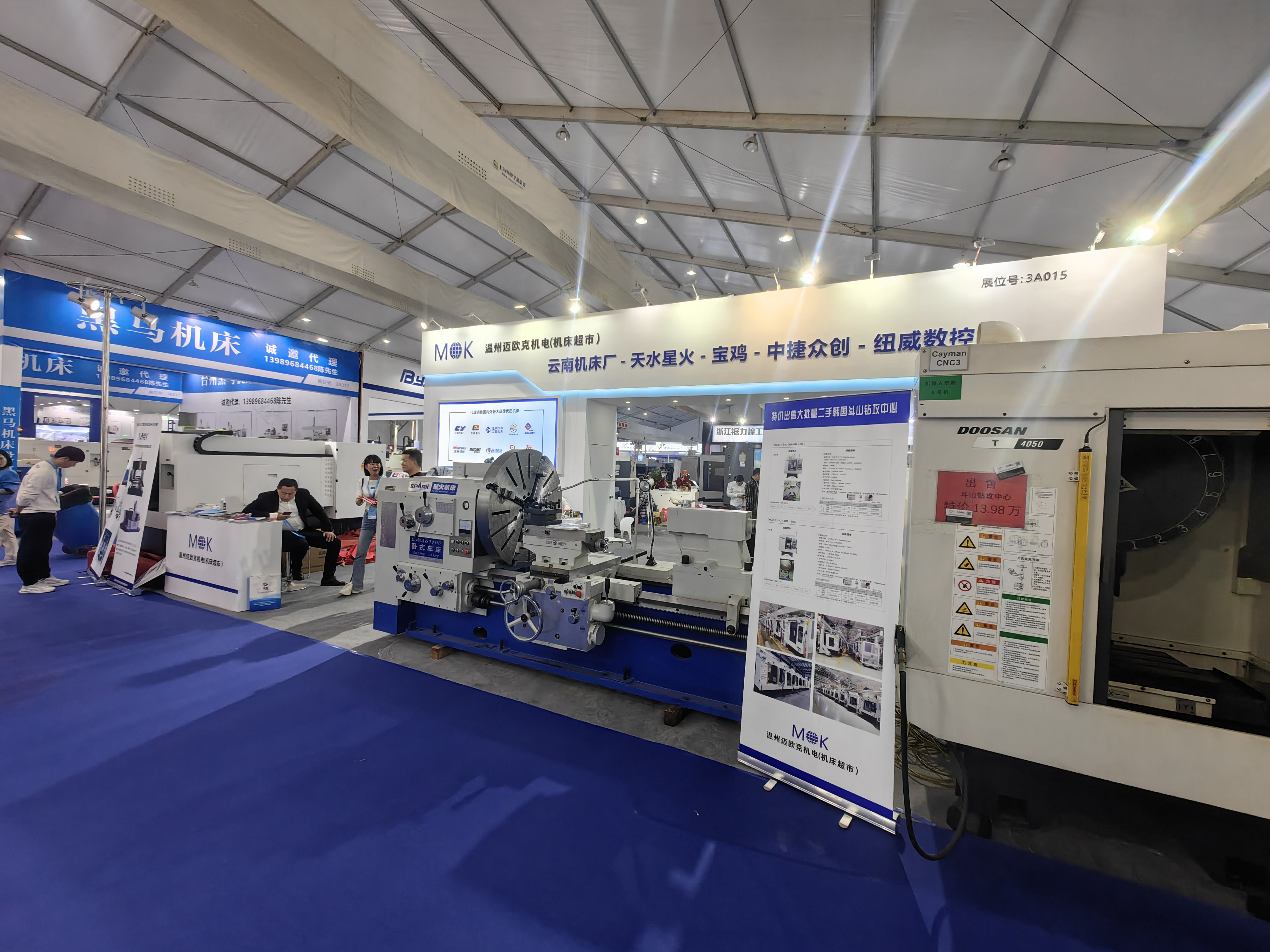

MOK Successful Participation in the 30th Wenzhou International Industrial Expo – A Complete Round Up

MOK Successfully Participates in the 30th Wenzhou International Industrial Expo – A Complete Round Up Wenzhou Maiouke Electromechanical Equipment Co., Ltd. (MOK) recently participated in the 30th Wenzhou International Industrial Expo, presenting its newest and most innovative manufacturing and pr...Read more -

About the construction of CNC machining center analysis

The host part of a CNC machining center plays a crucial role in the overall performance of the machine. The CNC machining center bed, spindle box, table, base, column, beam, and feed mechanism provide the necessary mechanical support for the machining process. The CNC machining center bed is the ...Read more -

What are the maintenance points of horizontal machining center?

What are the maintenance points of Horizontal machining center ? Horizontal machining center plays a very important role in our practical application, when we apply horizontal machining center, how to carry out new maintenance in horizontal machining? I came to lead you to understand what are the...Read more -

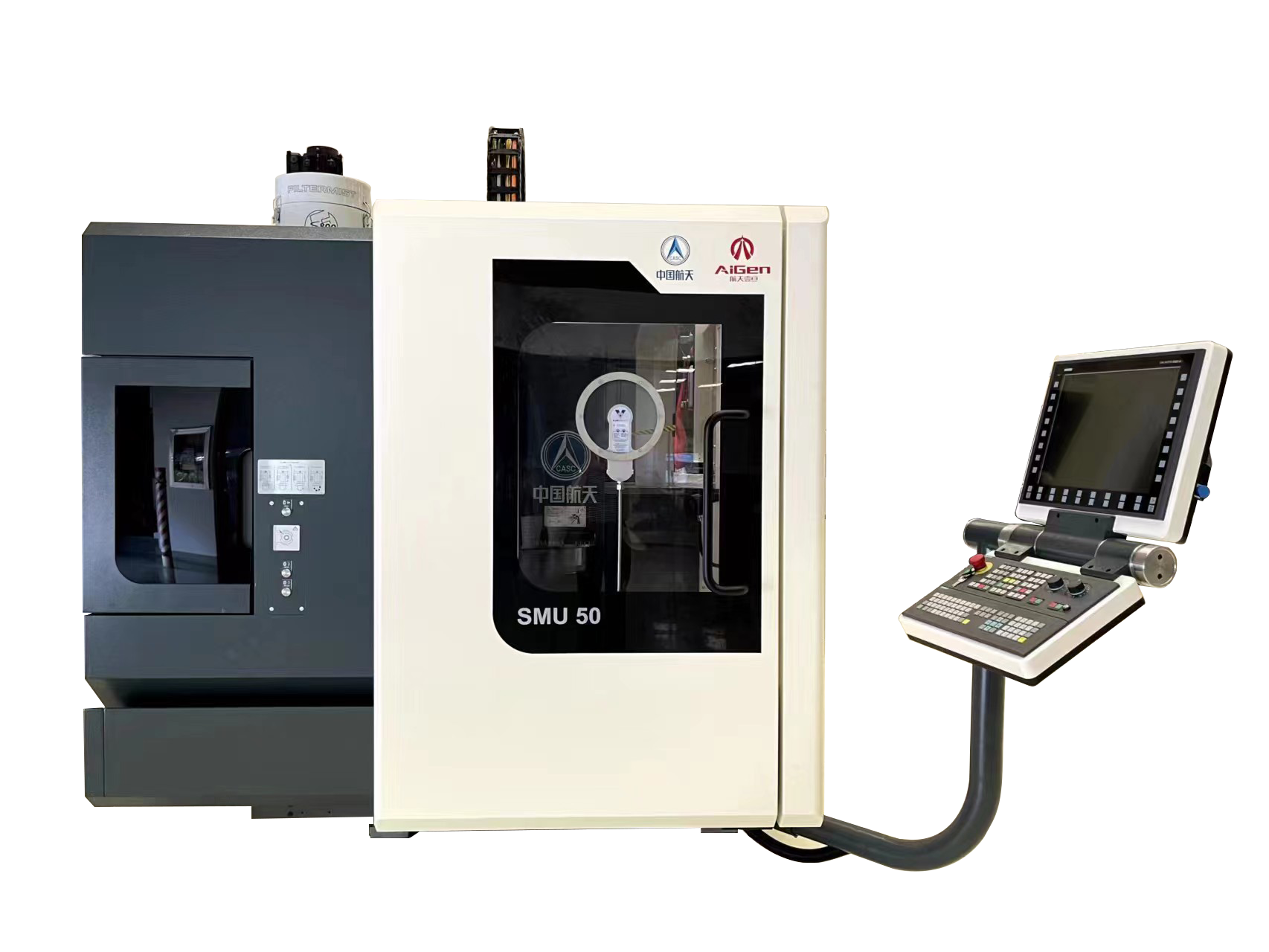

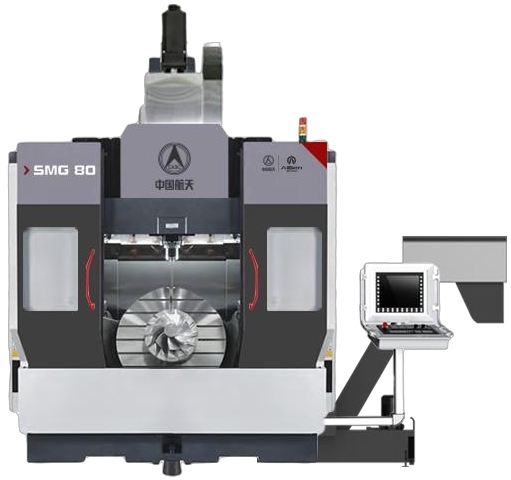

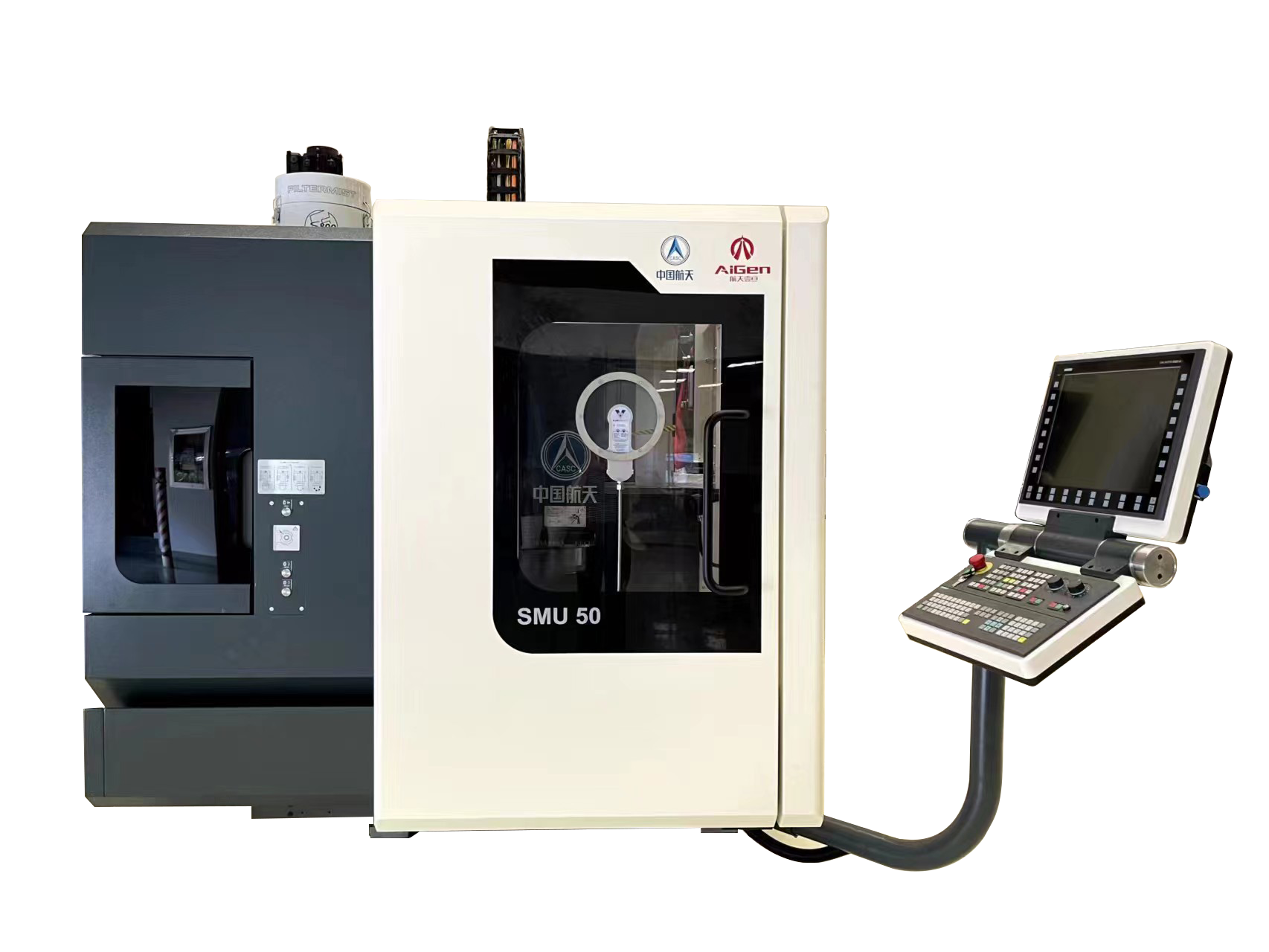

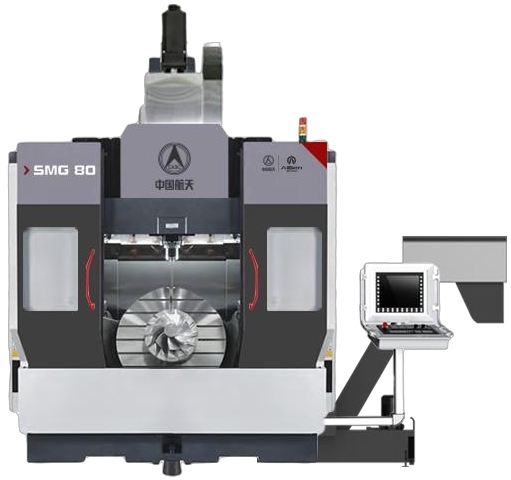

Five-axis machining centre in the use of which points are easy to be ignored?

When it comes to machining complex and intricate parts, 5-axis machines have significant advantages over traditional 3-axis machines. While 3-axis machines are capable of producing a wide range of shapes and forms, they are limited by the fact that the axis direction of the tool always remains th...Read more -

A summary of 5-axis machining centre accuracy and reduction of failure rates

5-axis machining centres are a game-changer in the manufacturing industry. By integrating milling, engraving, cutting, punching, dicing, and slotting into one machine, they make it possible to process complex workpieces with ease. This technology not only improves machining accuracy and flexibili...Read more -

CNC turning machining center, don’t miss it

CNC turning machining centers are becoming increasingly popular in the manufacturing industry due to their numerous advantages over traditional machining methods. CNC turning machining centers are capable of producing high-precision parts with a level of accuracy that is difficult to achieve with...Read more