OEM/ODM Supplier CNC Glass Drilling and Milling Machine CNC Vertical Glass Working Center

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for OEM/ODM Supplier CNC Glass Drilling and Milling Machine CNC Vertical Glass Working Center, In case you have any comments about our company or products and solutions, make sure you feel free of charge to speak to us, your coming mail might be highly appreciated.

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for China Vertical Glass Drilling and Milling Machine and Glass Drilling and Milling Machine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have now implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our goods have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.

Specification

|

Item |

Unit |

VMC 850Q |

VMC 1000Q |

VMC 1100Q |

|

| Table | |||||

|

Table size |

mm |

1000×500 |

1150×500 |

1300×610 |

|

|

Max.allowed loading |

kg |

600 |

600 |

1000 |

|

|

T slot size |

mm×N |

18×5 |

18×5 |

18×5 |

|

| Machining range | |||||

|

X axis travel |

mm |

850 |

1000 |

1100 |

|

|

Y axis travel |

mm |

500 |

500 |

620 |

|

|

Z axis travel |

mm |

540 |

540 |

600 |

|

|

Distence between |

Max. |

mm |

660 |

660 |

720 |

|

Min. |

mm |

120 |

120 |

120 |

|

|

Distence between spindle center to guideway surface |

mm |

640 |

640 |

743 |

|

| Spindle | |||||

|

Taper (7:24) |

- |

BT40 |

BT40 |

BT40 |

|

|

Speed |

r/min |

10000 |

10000 |

10000 |

|

|

Torque |

N.m |

35.8/70 (S2 15Minutes) |

35.8/70 (S2 15Minutes) |

35.8/70 (S2 15 Minutes) |

|

|

Main motor power |

kW |

7.5/11 |

7.5/11 |

7.5/11 |

|

|

Drive type |

- |

Synchrono us belt |

Synchrono us belt |

Synchrono us belt |

|

| Tooling | |||||

|

Tool holder |

- |

MAS 403 BT40 |

MAS 403 BT40 |

MAS 403 BT40 |

|

|

Pull stud |

- |

MAS 403 40BT- 1 |

MAS 403 40BT- 1 |

MAS 403 40BT- 1 |

|

| Feed | |||||

|

Rapid feed |

X axis |

m/min |

48 |

48 |

48 |

|

Y axis |

m/min |

48 |

48 |

48 |

|

|

Z axis |

m/min |

48 |

48 |

48 |

|

|

Motor power(XYZ) |

kW |

1.8/1.8/3 |

1.8/1.8/3 |

3/3/3 |

|

|

Motor torque(XYZ) |

Nm |

11/11/20 |

11/11/20 |

20/20/20 |

|

|

Feeding speed |

mm/min |

1-20000 |

1-20000 |

1-20000 |

|

| Toot Magazine | |||||

|

Type |

- |

Robot |

Robot |

Robot |

|

|

Tool collection |

- |

Nearest tool selection |

Nearest tool selection |

Nearest tool selection |

|

|

Magazine capacity |

- |

24 |

24 |

24 |

|

|

Max.tool length |

mm |

300 |

300 |

300 |

|

|

Max.tool weight |

kg |

7 |

7 |

7 |

|

|

Max.tool disk dia. |

Full |

mm |

Φ80 |

Φ80 |

Φ80 |

|

Nearby |

mm |

Φ150 |

Φ150 |

Φ150 |

|

|

Tool change time |

s |

2.5 |

2.5 |

2.5 |

|

|

Distence between table to ground |

mm |

880 |

880 |

950 |

|

|

Machine weight |

kg |

5100 |

5400 |

6200 |

|

|

Electricity capacity |

KVA |

18 |

18 |

25 |

|

|

Overall Dimensions (L×W×H) |

mm |

2400×2560×2700 (without conveyor) |

2700× 2560 × 2700 (without conveyor) |

2940× 3450×3050 (without conveyor) |

|

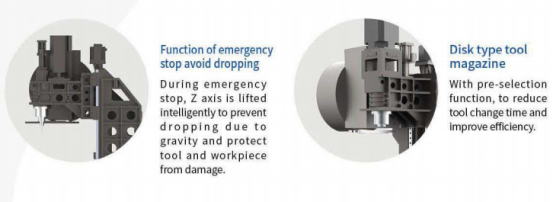

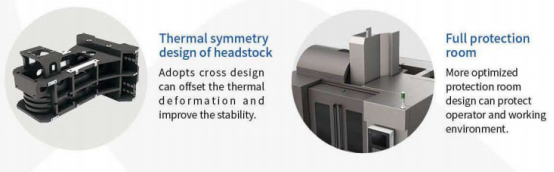

Characteristic

Samples

Factory Tour

We insist on offering high-quality production with great enterprise concept, honest product sales and also the finest and fast service. it will bring you not only the superior quality solution and huge profit, but the most significant should be to occupy the endless market for OEM/ODM Supplier CNC Glass Drilling and Milling Machine CNC Vertical Glass Working Center, In case you have any comments about our company or products and solutions, make sure you feel free of charge to speak to us, your coming mail might be highly appreciated.

OEM/ODM Supplier China Vertical Glass Drilling and Milling Machine and Glass Drilling and Milling Machine, We care about every steps of our services, from factory selection, product development & design, price negotiation, inspection, shipping to aftermarket. We have now implemented a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our goods have been strictly inspected before shipment. Your Success, Our Glory: Our aim is to help customers realize their goals. We’re making great efforts to achieve this win-win situation and sincerely welcome you to join us.