SHENYANG(SMTCL) Vertical Machining Center VMC1300B

Specification

|

Items |

Unit |

VMC1300B |

||

| Table | ||||

|

Table size |

mm |

1400×700 |

||

|

Slot size |

mm |

18×5 |

||

|

Max. Loading |

kg |

1000 |

||

| Working range | ||||

|

X axis travel |

mm |

1300 |

||

|

Y axis travel |

mm |

700 |

||

|

Z axis travel |

mm |

700 |

||

|

Max. distance between spindle nose to working table |

mm |

850 |

||

|

Min.distance between spindle nose to working table |

mm |

150 |

||

| Spindle | ||||

|

Tapper |

- |

BT40 |

BT50 |

|

|

Spindle speed |

r/min |

10000 |

6000 |

|

|

Main motor torque |

N.m |

52.5 |

71.6 |

|

|

Main motor power |

kW |

11/15 |

15/18.5 |

|

| Feeding | ||||

|

Feeding speed |

mm/min |

1-10000 |

||

|

Rapid feeding x/y/z |

m/min |

24/24/20 |

||

| Magazine | ||||

|

Magazine type |

- |

ATC |

||

|

Magazine capacity |

piece |

24 |

20 |

|

|

Max.tooling length |

mm |

300 |

300 |

|

|

Max.tooling weight |

kg |

7 |

15 |

|

|

Max.tooling diameter |

Full |

mm |

Φ80 |

Φ133 |

|

Near |

mm |

150 |

250 |

|

|

Tooling change time |

s |

2.5 |

3.5 |

|

| Positioning | ||||

|

X axis |

mm |

0.010 |

||

|

Y axis |

mm |

0.008 |

||

|

Z axis |

mm |

0.010 |

||

| Repeatability | ||||

|

X axis |

mm |

0.008 |

||

|

Y axis |

mm |

0.006 |

||

|

Z axis |

mm |

0.008 |

||

|

General electricity capacity |

kVA |

37 |

||

|

Air pressure |

Mpa |

0.5-0.7 |

||

| Machine dimensions and weight | ||||

|

Dimensions(L×W×H) |

mm |

5026 ×2970 ×3361 |

||

|

Weight |

kg |

9500 |

||

|

Controller |

- |

FANUC |

||

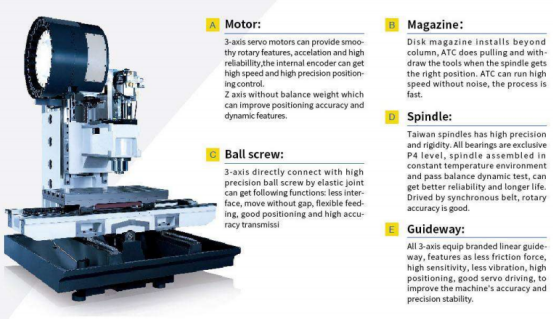

The VMC1300B vertical machining centre is one of the products developed by our company with independent intellectual property rights. The extra wide bed design ensures the machine has the best support and stability, and the bed adopts a large bevel structure and a split guard for the Y-axis, making chip removal easy and fast. It provides the perfect solution for the processing of components in many industries.

The machine tool adopts electromechanical integration structure and applies 3D design software (Pro/E) and finite element analysis software (Ansys) to optimize the design, which makes the machine structure design more reasonable and the machine rigidity, precision maintenance and reliability close to perfection. Through the introduction of advanced design concepts and scientific design methods, the shortcomings that cannot be avoided by traditional design have been solved.