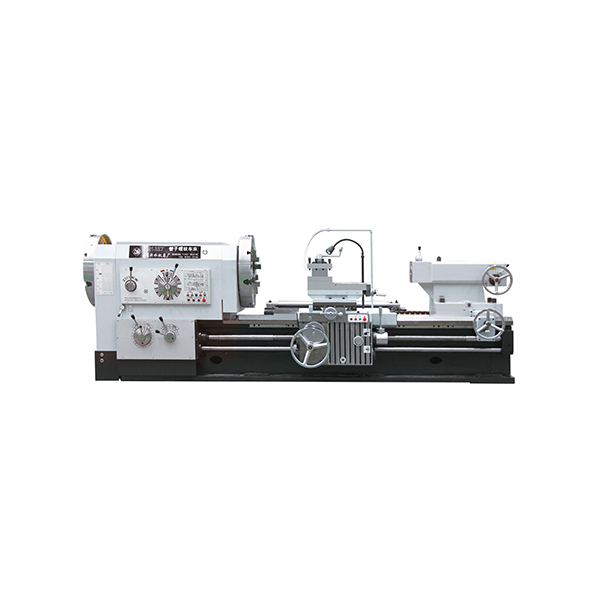

YISHUI Conventional Pipe threading lathe Q1325C Q1327C Q1327

Specification

|

Item |

Unit |

Q1325C |

Q1327C |

Q1327 |

|

|

Capacity |

Swing over bed |

mm |

800 |

800 |

1000 |

|

Swing over cross slide |

mm |

480 |

480 |

610 |

|

|

Distance between centers |

mm |

1500/3000 |

1500/3000 |

1500/3000 |

|

|

Pipe threading range |

mm |

50-250 |

50-270 |

130-270 |

|

|

Spindle |

Guideway width |

mm |

600 |

600 |

755 |

|

Max. load capacity |

T |

4 |

4 |

6 |

|

|

Spindle bore |

mm |

255 |

280 |

280 |

|

|

Spindle speed steps |

- |

VF.4 steps |

VF.4 steps |

FWD. 12 steps |

|

|

Spindle speed range |

rpm |

20-420 |

20-420 |

16-380 |

|

|

Chuck |

mm |

Φ630 4-jaw manual |

Φ680 4-jaw electric |

Φ800 4-jaw electric |

|

|

Turret |

Turret/tool post |

- |

Manual 4 position |

Manual 4 position |

Manual 4 position |

|

Tool shank size |

mm |

32×32 |

32×32 |

45×45 |

|

|

Feed |

X axis travel |

mm |

420 |

420 |

520 |

|

Z axis travel |

mm |

1250/2750 |

1250/2750 |

1350/2850 |

|

|

X axis feed grade/range |

mm/r |

22/0.02-0.45 |

22/0.02-0.45 |

40/0.05-1.5 |

|

|

Z axis feed grade/range |

mm/r |

26/0.07-1.33 |

26/0.07-1.33 |

40/0.1-3 |

|

|

X axis rapid traverse |

mm/min |

2300 |

2300 |

1870 |

|

|

Z axis rapid traverse |

mm/min |

4000 |

4000 |

3740 |

|

|

Metric thread grade/range |

mm |

1-15 |

1-15 |

30/1-30 |

|

|

Inch threadgrade/range |

T.P.I |

14-1 |

14-1 |

27/28-1 |

|

|

Tailstock |

Tailstock quill diameter |

mm |

Φ120 |

Φ120 |

Φ160 |

|

Tailstock quill taper |

- |

MT6 |

MT6 |

MT6 |

|

|

Tailstock quill travel |

mm |

250 |

250 |

300 |

|

|

Motor |

Main spindle motor |

kW |

15 |

15 |

22 |

|

Rapid traverse motor |

kW |

1.1 |

1.1 |

1.5 |

|

|

Coolant pump motor |

kW |

0.125 |

0.125 |

0.125 |

|

|

Dimension |

Width×Height |

mm |

1700×1600 |

1700×1600 |

2100×1650 |

|

Length |

mm |

4100/5600 |

4100/5600 |

4900/6400 |

|

|

Weight |

Net weight |

T |

8.0/9.0 |

8.0/9.0 |

10.0/11.5 |

|

Please note: machine bed length can customize according to real work demand. |

|||||

Characteristic

●Big spindle bore and double chuck to ensure process big diameter pipe.

●Integral machine bed adopts high strength iron to realize.

●Ultrasonic frequency quenched guide-ways ensure good wear-resistance.

●Equipped with taper guide bar device this enables the machine to process taper threads.

Factory Tour